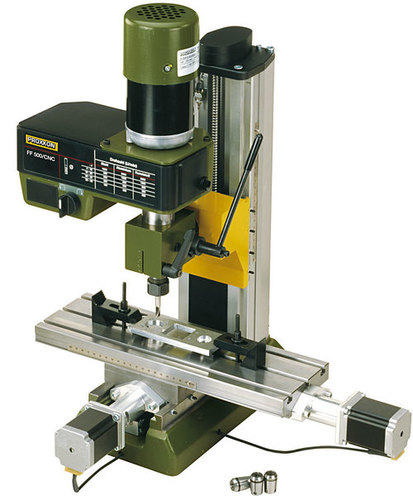

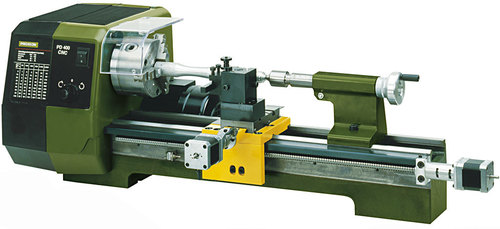

With double roller bearing recirculating ball spindles at all 3 axes and 3 powerful step motors for driving compound table and milling head.

Large travel distances: X-axis: approx. 290mm, Y-axis: approx. 100mm, Z-axis: approx. 200mm.

Stable column with dovetail slideway.

Including user-friendly software. Runs under WINDOWS (see description below).

Thanks to CNC control of 3 tool axes machining of steel and non-ferrous metals is possible in all dimensions. This also applies to larger work pieces

Axes drive with recirculating ball spindles (no backlash) and powerful step motors. Otherwise the mechanical design is almost identical to the MICRO miller FF 500: Solid, flat-milled compound table in steel with 3 continuous T-slots for size 8 standard T-nuts. Base of vibration-damping cast steel. Stable column with dovetail slideway. Milling head can be pivoted to the left and right by 90, with powerful, quiet and shock-free running condenser motor. Poly V-belt drive for 6 spindle speeds (180 - 2,500/min). Additional sleeve feed (30mm) using drilling lever with scale ring (1 graduation line = 1mm). Work piece fixing using steel collets.

Complete with CNC control unit, CNC programme software, all connecting cables, one each steel collets 6 - 8 - 10 and 12mm and detailed manual.

NO 24 340

Note:

Since the mechanical design of the FF 500/CNC is almost identical to the FF 500, the accessories supplied for it can be used without restriction. This also applies to the dividing attachment UT 400/CNC for the 4th axis!

Powerful, quiet and shock-free running condenser motor (400W).

Flat-milled table in steel (400 x 125mm) with 3 continuous T-nuts.

Step motor for Y-axis (travel distance approx. 100mm).

Step motor for X-axis (travel distance approx. 290mm).

Stable column with dovetail slideway.

Recirculating ball spindle for Z-axis. Drive via step motor mounted in column (travel distance approx. 200mm).

PROXXON CAD/CAM software for WINDOWS

Brief description of software and hardware:

The software is harmonized with mechanics, motors and the control unit of the CNC machine, thus offering the optimum performance.

The CNC control unit controls the step motors of the machine. The PC software provides the machine with the geometry information for travel of the tools (via RS 232 interface). This means that the control unit is the interface between software and the mechanics of the machine.

Powerful micro processors and accordingly dimensioned step motors and phases ensure that the motors always provide enough power for any machining processes. Two freely usable output relays in the casing of the control unit provide facilities for control of additional functions, e.g. a working lamp. Including connection cables with suitable plugs and built-in power supply for connection to 220 - 240V.

CNC simulation

If requested, the travel distances of the tool are simulated in the graphic window. In this way, faults in the programming can be recognised in time.

Manual work

The handwheels are replaced with the step motors of the CNC machine. Nevertheless, manual machining is possible with the help of cursor buttons, since the step motors can be operated manually.

Software installation

The PC software is supplied on a CD ROM. The problem-free installation is effected under WINDOWS as usual.

Note:

PC or laptop are not part of the scope of delivery. Minimum requirements for the hardware: Pentium processor with 400 MHz frequency (or comparable), high-quality graphic card (64 MB RAM) and at least 40 MB free hard disc storage.